+63917-5984553

2nd Floor, Carmel Estates, Bldg J. Camus Ext.

Brgy 7-A (Pob.) Davao City, Davao Del Sur

Newsletter

How FIBCs Are Manufactured from Thread to Transport

Ever held a bulk bag and wondered how something so simple-looking could be so strong, reliable, and versatile?

Flexible Intermediate Bulk Containers (FIBCs)—often called bulk bags—are essential in industries ranging from agriculture and construction to pharmaceuticals and chemicals. But behind their seemingly straightforward design lies a meticulous, multi-step manufacturing process that ensures strength, durability, and safety.

Let’s take a behind-the-scenes look at how FIBCs are crafted—from raw material to ready-for-use.

1. Extrusion: Where It All Begins

It starts with melting a precise mix of virgin polypropylene granules, UV inhibitors, and sometimes calcium carbonate. This molten blend is extruded into flat tapes—the building blocks of FIBCs. Pigments can also be added at this stage to give the fabric its color.

2. Weaving: Threads That Hold It Together

These tapes are then woven into fabric on large looms. The result is a durable, high-tensile cloth capable of withstanding heavy industrial use. At this stage, the fabric is breathable, but not yet moisture-resistant—an important factor for certain products.

3. Laminating: Extra Protection When Needed

Depending on the intended use, the fabric may be laminated with a moisture-resistant layer. This step is crucial for bulk bags meant to carry powders, grains, salt, sugar, and other products that must be protected from humidity or water exposure.

4. Cutting: Precision in Every Piece

The woven or laminated fabric is fed into automated cutting machines to create panels in specific shapes—square, tubular, or rectangular—based on the client’s design. Accuracy here is vital to ensure consistent quality and strength.

5. Printing: Brand It Your Way

Once the panels are cut, they head to the printing section. Logos, handling instructions, color codes, and branding details are printed using heavy-duty machinery that ensures durability, even in tough handling conditions.

6. Webbing: Crafting the Lifting Loops

This step involves creating the handles. Using heavier tapes and strong multifilament thread, lifting loops or straps are woven for maximum strength—allowing forklifts and cranes to lift the bags safely and easily.

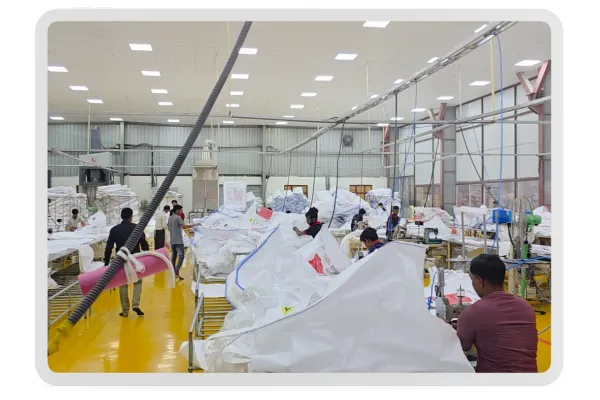

7. Sewing: Bringing It All Together

Now comes the assembly. Skilled operators stitch the panels, loops, and liners together using industrial sewing machines. Every seam, fold, and stitch is made with precision to ensure the bag performs flawlessly under pressure.

8. Inspection: Quality You Can Trust

No bulk bag leaves the factory without passing inspection. Each one is checked for stitching, shape, and durability. Only bags that meet rigorous standards move forward. They’re also tested for Safe Working Load (SWL) to guarantee their reliability in the field.

9. Packing: Ready for the Road

Finished bags are compressed using a bale press, making them compact for storage and easy transport. Bundled and packed, they’re now prepped for bulk delivery.

10. Storage: Awaiting Deployment

Finally, the bags are stored in clean, organized spaces, ready to be dispatched to clients across industries—whether it’s for hauling gravel on a construction site, storing agricultural feed, or transporting pharmaceutical powders.

Quality is in the Details.

Every step in the FIBC manufacturing process is fine-tuned for performance. From thread thickness to UV protection, from handle strength to stitching quality—nothing is left to chance.

At Premier JGL Resources, in partnership with Leading Manufacturers of FIBC Bags, we don’t just make bulk bags. We engineer them for excellence.

Need high-quality, industry-specific FIBCs? Let’s talk.